Blog

Many organizations that use plastic products do not necessarily manufacture them on their own. There are plastic manufacturing companies that offer production services, but don't offer a comprehensive service to create and distribute your product. Like everything in business, you need to make an informed choice when selecting a top plastic manufacturing company for your products. Your products are one of the most important aspects of your business, so deciding who to trust with them is a big decision.

When it comes to plastic injection molding, there's room for several errors. Quality issues in plastic injection-molded items range from negligible surface defects to severe problems that affect the performance, safety, as well as function of the final product. Often times, the flaws are linked to the material used, tooling design, molding process, or a combination of all three.

Despite living in the world's greatest nation, it has become tough to find items labeled "Made in America" in recent times. In fact, according to the Washington Post, 98% of shoes worn in the US are made abroad. Then, when you think about plastics, food items, electronics, and a surplus of items used regularly that are made overseas, you may wonder if Americans are producing anything.

Sustainability has been defined as: "The quality of not being harmful to the environment or depleting natural resources, and thereby supporting long-term ecological balance." Another definition of sustainability that applies to the manufacturing industry is a process or approach that “focuses on meeting the needs of the present without compromising the ability of future generations to meet their needs."

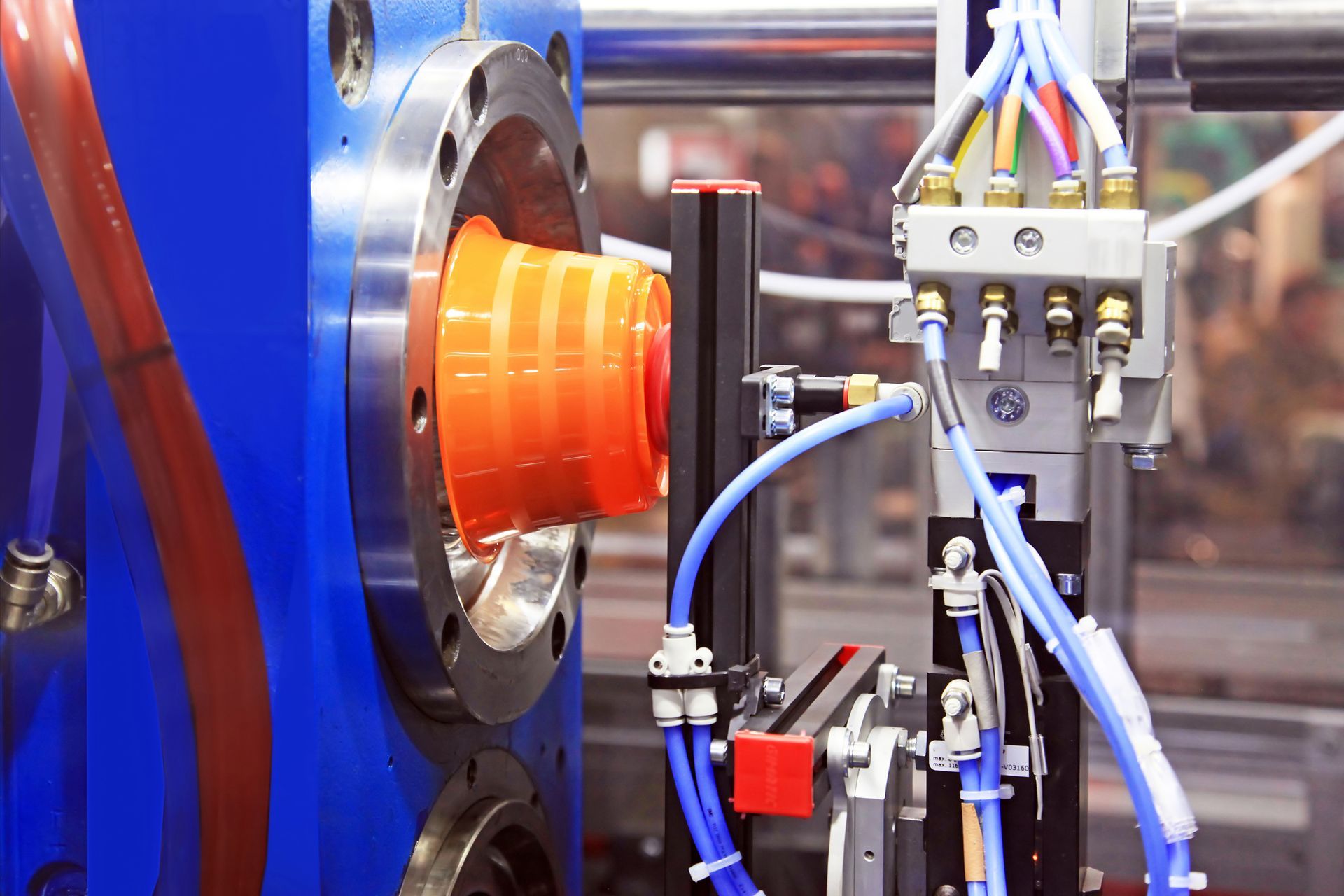

Plastic products made for babies and toddlers are often created using injection molding, a specialty of our company. Injection molding is a manufacturing process where molten substances are injected into a mold. This allows a product to be manufactured many times over. Remember when you were a child and you used a plastic fork to eat a birthday cake at a friend's birthday party? It was almost certainly made using an injection molding process. But are these products safe for babies and toddlers

Companies have turned to the use of plastic injection molding technology to manufacture plastic parts and products on a massive scale. Injection molding involves melting plastic before injecting it into the mold that shapes it into the desired form before cooling to produce the final product. This product may require a custom color to improve its aesthetic appeal and purchase rate. Molding companies have to add color to the raw plastic to achieve this feat. Common color plastic products include