What Is 2D and 3D CAD Modeling?

2D and 3D CAD Modeling in NY & NJ

CAD modeling involves the use of computer software to create detailed digital representations of parts and products. These models are essential for visualizing and testing product designs before entering the manufacturing phase. With 2D CAD modeling, we create flat representations of products that focus on the shape, size, and layout.

Benefits of CAD Modeling at Bennett Plastics

Precision & Accuracy

With our advanced CAD software, we can produce highly accurate models that ensure your product meets all design specifications and tolerances.

Product Visualization

Our 3D CAD models allow you to visualize your product from every angle, giving you a clear understanding of how the final product will look and function.

Design Optimization

Using CAD modeling, we can simulate the injection molding process, identifying potential issues related to mold flow, cooling, and part warping.

Faster Prototyping & Production

CAD modeling significantly reduces the time between the initial concept and production.

For more information, call us at (973) 684-1501 or visit our

contact page.

Our 2D and 3D CAD Modeling Process

1. Concept Development

Whether you have a rough sketch or a detailed design, our team will work with you to ensure the product’s dimensions and functionality are clearly defined.

2. 2D CAD Modeling

For simpler designs or the initial stages of product development, we create 2D drawings that outline the product’s dimensions, layout, and key features.

3. 3D CAD Modeling

Using cutting-edge 3D modeling software, we generate a full three-dimensional representation of your product.

4. Design Review & Optimization

Our team will suggest improvements to enhance performance and manufacturability, and reduce production costs.

5. Prototyping

After finalizing the CAD model, we can move quickly into prototyping, either through 3D printing or other traditional methods.

6. Final Design & Manufacturing

Once the design is validated through prototyping, we provide detailed specifications to support the injection molding process.

Experience the Benefits of CAD Modeling at Bennett Plastics

At Bennett Plastics, we leverage the latest in 2D and 3D CAD modeling technology to ensure your American-made product is ready for mass production with minimal revisions. Our experienced engineers work closely with you to develop designs that meet your exact specifications, resulting in faster production times, reduced costs, and superior performance.

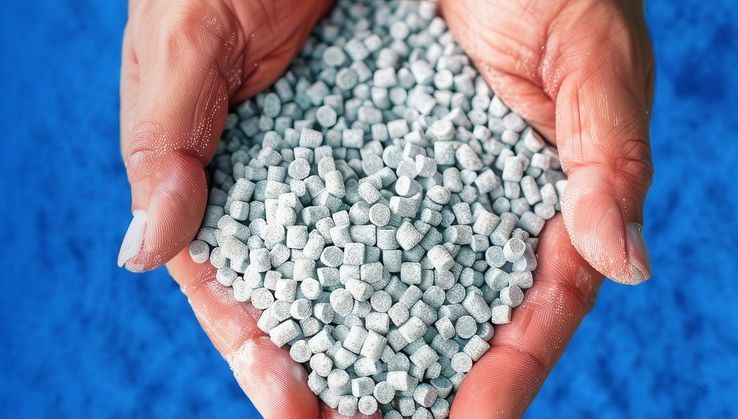

Sustainability for Innovative Manufacturing

We are dedicated to sustainability by using eco-friendly materials such as bio-based and recycled plastics in our manufacturing process, ensuring that our products meet high-quality standards and contribute to a healthier planet.

The Bennett Plastics Advantage

Direct Communication

Experience seamless collaboration with Bennett Plastics. We maintain open, direct lines of communication throughout the entire manufacturing process.

On-Site Manufacturing

All production is handled in-house at our Paterson, NJ facility. This allows us to maintain strict quality control and deliver products that meet our high standards.

No Outsourcing

Your projects are managed entirely by our skilled team. We never outsource, so you can trust that every part we produce is crafted with precision, right in the USA.

Fast Delivery

Our efficient processes and local manufacturing enable us to deliver your products quickly, reducing lead times and keeping your projects on schedule.