What Is Plastic Injection Molding?

Plastic Injection Molding Manufacturers in NJ

Plastic injection molding is a manufacturing process that injects molten materials like glass, various polymers, elastomers, confections, and metals (usually referred to as die-casting) into a pre-designed form or mold. This allows for the mass production of a single item or component in a simple or complex shape in a single process, which can be joined or fastened to other parts in an assembly.

The Benefits of Injection Molding

Rapid Production

Plastic injection molding allows for the swift production of large volumes of parts, significantly reducing lead times and keeping up with high-demand manufacturing schedules.

Complex Geometries

Injection molding enables the capability of producing intricate shapes and detailed features for your project.

Versatility

With the ability to create complex shapes and accommodate a wide range of materials, plastic injection molding is versatile enough to meet needs of many industries.

Precision Molding

Advanced mold design and tight tolerances ensure that each part produced through plastic injection molding meets specifications with minimal need for adjustments.

For more information, call us at (973) 684-1501 or visit our

contact page.

Our Injection Molding Process

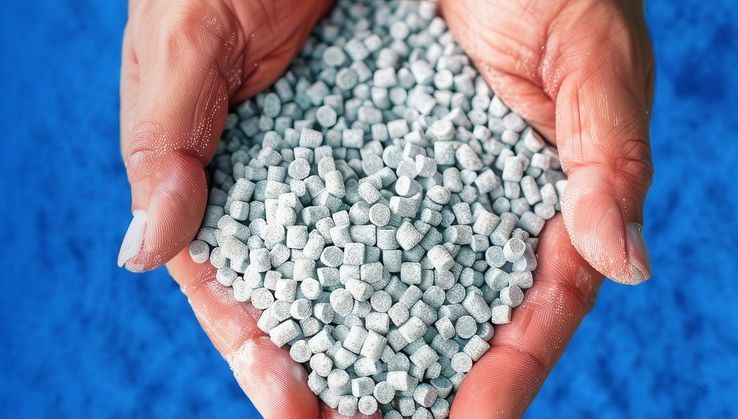

1. Material Preparation

We carefully choose the appropriate materials for each project and then melt the plastic pellets in an injection molding machine.

2. Injection

The selected materials are injected into the mold cavity with precise control, forming the foundation of the product’s structure.

3. Mold Cooling

After melting and injection, the mold is cooled uniformly to maintain the integrity of the product’s shape and properties.

4. Ejection

Once the material has solidified, the formed part is safely removed from the mold, ready for further processing.

5. Quality Inspection

Each part undergoes a thorough quality inspection to ensure it meets all design and performance criteria before moving to the next stage.

6. Packaging & Shipping

Finally, the finished products are carefully packaged and shipped to our clients, ensuring they arrive in perfect condition and on time.

Experience the Excellence of American-Made Injection Molding

At Bennett Plastics, our commitment to quality, precision, and customer satisfaction sets us apart in the injection molding industry. Partner with us today to bring your next project to life with the reliability and efficiency that only a trusted, local manufacturer can offer.

Sustainability for Innovative Manufacturing

We are dedicated to sustainability by using eco-friendly materials such as bio-based and recycled plastics in our manufacturing process, ensuring that our products meet high-quality standards and contribute to a healthier planet.

The Bennett Plastics Advantage

Direct Communication

Experience seamless collaboration with Bennett Plastics. We maintain open, direct lines of communication throughout the entire manufacturing process.

On-Site Manufacturing

All production is handled in-house at our Paterson, NJ facility. This allows us to maintain strict quality control and deliver products that meet our high standards.

No Outsourcing

Your projects are managed entirely by our skilled team. We never outsource, so you can trust that every part we produce is crafted with precision, right in the USA.

Fast Delivery

Our efficient processes and local manufacturing enable us to deliver your products quickly, reducing lead times and keeping your projects on schedule.