What Is Mold Making & Design?

Plastic Mold Making in Passaic County NJ

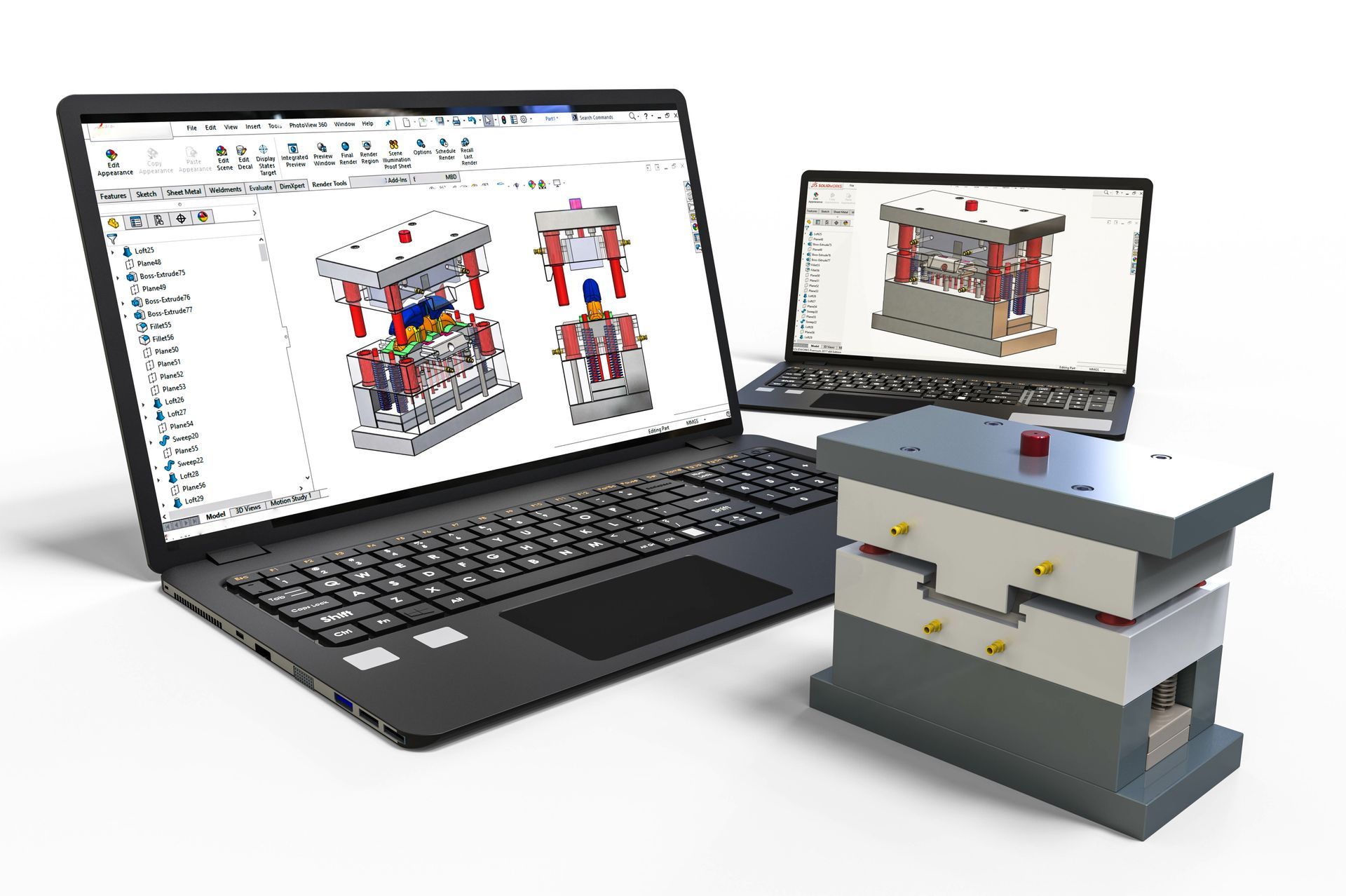

Mold making and design involve creating the custom molds used in plastic injection molding. This process is critical because the quality of the mold directly impacts the quality, consistency, and efficiency of the final product. Our mold-making process begins with detailed design work using advanced 3D modeling software, followed by the careful machining of the mold using high-grade materials.

The Benefits of Molding Making & Design

Customization & Precision

Every mold we design is customized to your exact specifications, using cutting-edge software.

Longevity & Durability

Our robust mold designs ensure long-term performance, even in high-volume production runs, reducing the need for frequent mold repairs or replacements.

Cost Efficiency

From optimizing part design for manufacturability to ensuring efficient cycle times, we help reduce material waste and lower overall production expenses.

Fast Turnaround Times

By handling mold design and production in-house, we control the entire process, ensuring fast lead times.

For more information, call us at (973) 684-1501 or visit our

contact page.

Our Mold Making & Design Process

1. Development

Our process begins with a detailed consultation to understand your product's requirements.

3. Mold Flow Analysis

To ensure efficient production and high-quality parts, we conduct mold flow analysis to identify potential issues.

4. Tooling & Machining

Once the design is finalized, we move to the tooling stage, where our skilled toolmakers create the mold using precision machining techniques.

5. Testing & Validation

After the mold is completed, we test it with sample production runs to ensure that it produces parts that meet your exact specifications.

6. Packaging & Shipping

We offer mold maintenance and support to ensure your molds continue to perform over the long term, including inspections, repairs, and adjustments.

Experience the Excellence of American-Made Mold Making

At Bennett Plastics, our commitment to quality, precision, and customer satisfaction sets us apart in the injection molding industry. Partner with us today to bring your next project to life with the reliability and efficiency that only a trusted, local manufacturer can offer.

Sustainability for Innovative Manufacturing

We are dedicated to sustainability by using eco-friendly materials such as bio-based and recycled plastics in our manufacturing process, ensuring that our products meet high-quality standards and contribute to a healthier planet.

The Bennett Plastics Advantage

Direct Communication

Experience seamless collaboration with Bennett Plastics. We maintain open, direct lines of communication throughout the entire manufacturing process.

On-Site Manufacturing

All production is handled in-house at our Paterson, NJ facility. This allows us to maintain strict quality control and deliver products that meet our high standards.

No Outsourcing

Your projects are managed entirely by our skilled team. We never outsource, so you can trust that every part we produce is crafted with precision, right in the USA.

Fast Delivery

Our efficient processes and local manufacturing enable us to deliver your products quickly, reducing lead times and keeping your projects on schedule.