What Is Vacuum Thermoforming?

Vacuum Thermoforming Manufacturers in NJ

Vacuum thermoforming is a manufacturing process that heats a plastic sheet until it becomes pliable, then forms it over a custom mold using vacuum pressure. This process is ideal for creating large, lightweight parts with intricate shapes or details in a single step. Vacuum thermoforming is commonly used in packaging, automotive, consumer goods, and other industries where high-quality plastic components are essential.

The Benefits of Vacuum Thermoforming

Cost-Effective

Vacuum thermoforming uses minimal material, resulting in lower production costs. Its ability to produce large, lightweight parts makes it a cost-effective solution for various industries.

Rapid Production

With fast setup times and the ability to produce large quantities of parts in a single run, vacuum thermoforming is an efficient process that can meet tight production deadlines.

Versatility

The thermoforming process allows for the creation of complex, detailed shapes that can be customized to meet specific design and functionality requirements.

Durability

Vacuum-formed products are strong and durable, making them ideal for a wide range of applications where long-lasting performance is essential.

For more information, call us at (973) 684-1501 or visit our

contact page.

Our Vacuum Thermoforming Process

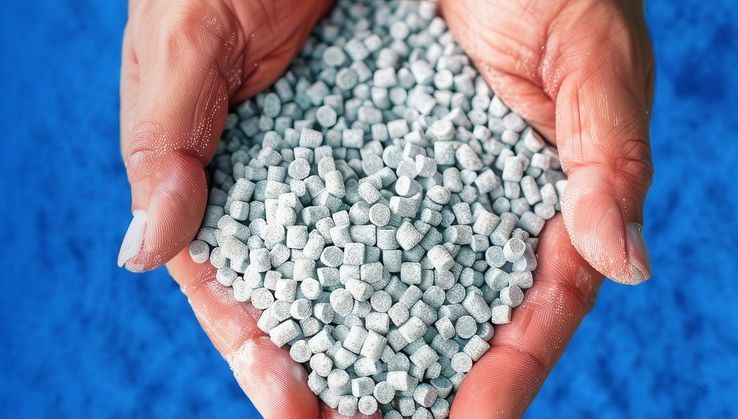

1. Material Selection

We begin by selecting choosing a thermoformable plastic sheet, ensuring the product meets all performance requirements.

2. Heating

The chosen plastic sheet is heated to a pliable state and is then ready to be molded into the desired shape you need.

3. Forming & Molding

The heated sheet is placed over a custom mold, and vacuum pressure is applied to form the plastic around the mold, capturing intricate details.

4. Cooling

The molded part is then cooled to solidify its shape and ensure structural integrity.

5. Cutting

After cooling, excess material is trimmed, and the finished part is carefully removed from the mold.

6. Quality Inspection

Each component undergoes an inspection to ensure it meets all design specifications standards.

Experience the Excellence of American-Made Vacuum Thermoforming

At Bennett Plastics, our commitment to quality, precision, and customer satisfaction sets us apart in the injection molding industry. Partner with us today to bring your next project to life with the reliability and efficiency that only a trusted, local manufacturer can offer.

Sustainability for Innovative Manufacturing

We are dedicated to sustainability by using eco-friendly materials such as bio-based and recycled plastics in our manufacturing process, ensuring that our products meet high-quality standards and contribute to a healthier planet.

The Bennett Plastics Advantage

Direct Communication

Experience seamless collaboration with Bennett Plastics. We maintain open, direct lines of communication throughout the entire manufacturing process.

On-Site Manufacturing

All production is handled in-house at our Paterson, NJ facility. This allows us to maintain strict quality control and deliver products that meet our high standards.

No Outsourcing

Your projects are managed entirely by our skilled team. We never outsource, so you can trust that every part we produce is crafted with precision, right in the USA.

Fast Delivery

Our efficient processes and local manufacturing enable us to deliver your products quickly, reducing lead times and keeping your projects on schedule.