What Is Multi Jet Fusion (MJF)?

MJF 3D Printing in New Jersey

Multi Jet Fusion (MJF) is an additive manufacturing process that uses a combination of agents and infrared light to fuse layers of powder into solid parts. Unlike other 3D printing methods, MJF produces parts with superior mechanical properties, consistent accuracy, and excellent surface finishes. It’s ideal for creating complex geometries, durable functional parts, and short production runs.

The Benefits of Multi Jet Fusion (MJF)

Fast Production

MJF technology allows for rapid printing, reducing lead times and helping you bring your product to market faster.

Strength & Durability

MJF produces parts with exceptional mechanical strength and durability, making it suitable for functional prototypes and end-use parts.

Design Flexibility

MJF can handle complex geometries and intricate designs without compromising strength or quality, providing flexibility in part creation.

Consistent Quality

With uniform material fusion across every layer, MJF delivers consistent, high-quality results across the entire part.

For more information, call us at (973) 684-1501 or visit our

contact page.

Our Multi Jet Fusion (MJF) Process

1. Design Consultation

We work closely with you to review your design and optimize it for the MJF process, ensuring it meets all performance and aesthetic requirements.

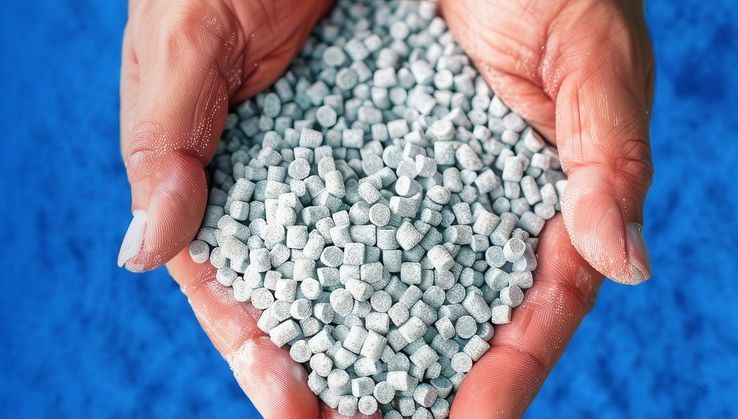

2. Material Selection

We offer a variety of materials suited for MJF, including nylon and other durable polymers, to match your project’s specific needs.

3. Powder Fusion

The MJF printer uses a series of inkjet-like printheads to apply fusing and detailing agents across each layer of powder.

4. Cooling & Powder Recovery

After printing, the part is cooled in a controlled environment, and the unused powder is reclaimed and recycled for future builds, minimizing waste.

5. Post-Processing

Parts can undergo various post-processing steps, such as bead blasting or dyeing, to improve aesthetics or functionality.

6. Quality Assurance

Every part is inspected to ensure it meets your specifications in terms of accuracy, strength, and surface finish.

Experience the Innovation of American-Made Multi Jet Fusion (MJF)

At Bennett Plastics, we are proud to offer high-performance MJF 3D printing services that deliver exceptional strength, speed, and accuracy. Whether you need durable prototypes or intricate, production-ready parts, our advanced MJF technology ensures reliable, efficient, and cost-effective solutions for a broad spectrum of industries. Partner with us to bring your designs to life with precision and durability you can count on.

Sustainability for Innovative Manufacturing

We are dedicated to sustainability by using eco-friendly materials such as bio-based and recycled plastics in our manufacturing process, ensuring that our products meet high-quality standards and contribute to a healthier planet.

The Bennett Plastics Advantage

Direct Communication

Experience seamless collaboration with Bennett Plastics. We maintain open, direct lines of communication throughout the entire manufacturing process.

On-Site Manufacturing

All production is handled in-house at our Paterson, NJ facility. This allows us to maintain strict quality control and deliver products that meet our high standards.

No Outsourcing

Your projects are managed entirely by our skilled team. We never outsource, so you can trust that every part we produce is crafted with precision, right in the USA.

Fast Delivery

Our efficient processes and local manufacturing enable us to deliver your products quickly, reducing lead times and keeping your projects on schedule.