What Is Casting?

Casting Manufacturing in Paterson NJ

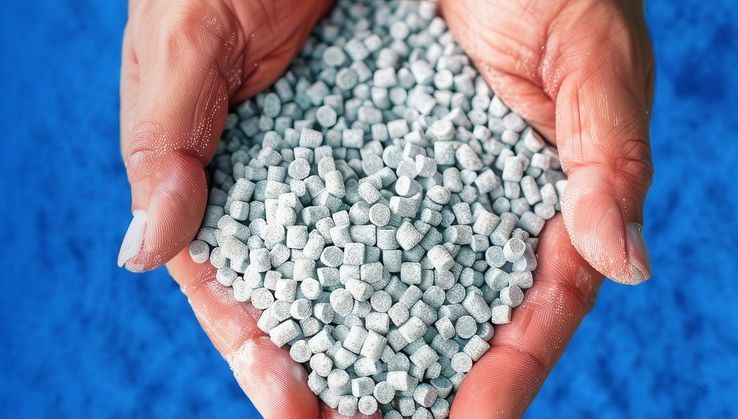

Casting is a manufacturing process where a liquid material is poured into a mold and allowed to solidify, forming a part or component. Once the material hardens, the mold is removed, leaving behind a finished product with the desired shape and dimensions. Casting is ideal for producing parts with complex geometries, high strength, and excellent dimensional accuracy. At Bennett Plastics, we specialize in a variety of casting processes, including urethane casting and metal casting, to suit diverse application needs.

The Benefits of Casting

Complex Designs

Casting allows for the production of parts with intricate designs and complex geometries that may be difficult to achieve through other manufacturing methods.

Versatile Materials

Casting can accommodate a wide range of materials, including metals, plastics, and urethanes, providing flexibility in part design and application.

Durable & Strong Parts

Cast parts are known for their strength and durability, making them ideal for functional components that need to withstand mechanical stress.

Cost-Effective

Casting is particularly cost-effective for small production runs or prototypes, offering high-quality results without the need for expensive tooling.

For more information, call us at (973) 684-1501 or visit our

contact page.

Our Casting Process

1. Design Consultation

We work with you to review your design and select the appropriate casting process and materials to meet your performance and cost requirements.

2. Mold Creation

A custom mold is created based on your design, ensuring that the final product meets the required dimensions and specifications.

3. Material Selection

We choose the optimal material for your project and pour it into the mold with precise control to ensure quality and consistency.

Cooling & Solidification

Once the material is poured, it is allowed to cool and solidify, taking on the exact shape of the mold.

5. Mold Removal & Finishing

After the part has fully solidified, the mold is carefully removed, and the part is inspected and refined as necessary.

6. Quality Inspection

Every cast part undergoes a thorough quality inspection to ensure it meets all performance standards.

Experience the Durability of American-Made Product With Casting at Bennett Plastics

Partner with Bennett Plastics for high-quality casting solutions that deliver durable, intricate parts with excellent dimensional accuracy. From design consultation to final production, we ensure every part meets your highest standards.

Sustainability for Innovative Manufacturing

We are dedicated to sustainability by using eco-friendly materials such as bio-based and recycled plastics in our manufacturing process, ensuring that our products meet high-quality standards and contribute to a healthier planet.

The Bennett Plastics Advantage

Direct Communication

Experience seamless collaboration with Bennett Plastics. We maintain open, direct lines of communication throughout the entire manufacturing process.

On-Site Manufacturing

All production is handled in-house at our Paterson, NJ facility. This allows us to maintain strict quality control and deliver products that meet our high standards.

No Outsourcing

Your projects are managed entirely by our skilled team. We never outsource, so you can trust that every part we produce is crafted with precision, right in the USA.

Fast Delivery

Our efficient processes and local manufacturing enable us to deliver your products quickly, reducing lead times and keeping your projects on schedule.