What Is Product Design for Manufacturing?

Product Design for Manufacturing in NY, NJ, & CT

Product Design for Manufacturing, or DFM, is the process of designing products with manufacturing efficiency in mind. This approach ensures that products are not only functional and aesthetically appealing but also cost-effective to produce and easy to manufacture at scale. By focusing on design elements that streamline production, DFM helps reduce material waste, optimize assembly, and improve overall product quality.

The Benefits of Product Design for Manufacturing

Cost-Effective Production

DFM optimizes the design process to reduce manufacturing costs by minimizing material waste.

Improved Product Quality

By designing with manufacturability in mind, we ensure that the final product meets stringent quality standards.

Reduced Lead Times

With a design optimized for manufacturing, production can begin quickly, reducing lead times and helping you get your product to market faster.

Scalability

Our DFM process ensures that your product design is scalable, allowing for seamless transitions from small production runs to full-scale mass manufacturing.

For more information, call us at (973) 684-1501 or visit our

contact page.

Our Product Design for Manufacturing Process

1. Initial Consultation

We begin with an in-depth consultation to understand your product concept, goals, and specific requirements.

2. Feasibility Analysis

We perform a thorough feasibility analysis to evaluate the manufacturability and functionality of the design.

3. Design Optimization

Our engineers work to optimize the product design, focusing on reducing material use, simplifying components, and improving assembly methods.

4. Prototype Development

Prototyping allows us to validate design choices and identify any final adjustments that may be needed before full production.

5. Testing & Refinement

After prototyping, we rigorously test the product to ensure it meets all design specifications, performance standards, and manufacturing requirements.

6. Manufacturing Support

Once the design is finalized, we provide full support during the manufacturing phase, working closely with production teams to ensure a smooth transition.

Experience the Excellence of American-Made Product Design for Manufacturing

At Bennett Plastics, we take pride in offering comprehensive Product Design for Manufacturing services that deliver high-quality, cost-effective solutions—all proudly made in the USA. Whether you’re developing a new product or refining an existing one, our team of experts is dedicated to helping you create designs that are ready for efficient, scalable production.

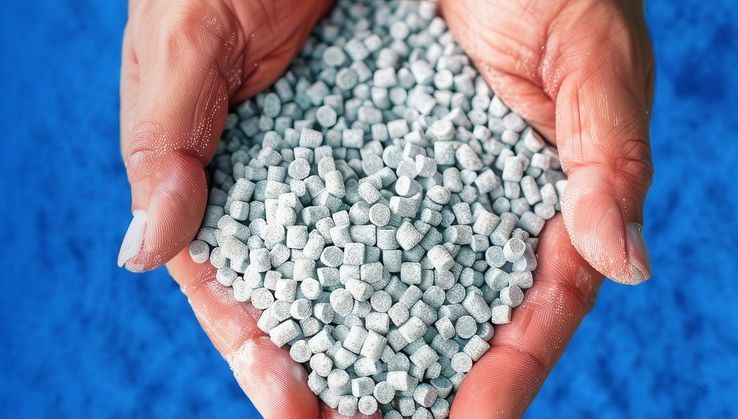

Sustainability for Innovative Manufacturing

We are dedicated to sustainability by using eco-friendly materials such as bio-based and recycled plastics in our manufacturing process, ensuring that our products meet high-quality standards and contribute to a healthier planet.

The Bennett Plastics Advantage

Direct Communication

Experience seamless collaboration with Bennett Plastics. We maintain open, direct lines of communication throughout the entire manufacturing process.

On-Site Manufacturing

All production is handled in-house at our Paterson, NJ facility. This allows us to maintain strict quality control and deliver products that meet our high standards.

No Outsourcing

Your projects are managed entirely by our skilled team. We never outsource, so you can trust that every part we produce is crafted with precision, right in the USA.

Fast Delivery

Our efficient processes and local manufacturing enable us to deliver your products quickly, reducing lead times and keeping your projects on schedule.