What Is Model Making & Sculpting?

Model Making & Sculpting Experts in NJ

Model making and sculpting is the process of creating physical representations of products, components, or art pieces, either as a prototype for mass production or as a one-of-a-kind custom design. Using a variety of materials such as clay, plastic, foam, or resin, this process allows for the creation of detailed, intricate models that can be used in industries such as entertainment, architecture, automotive, and more.

The Benefits of Model Making & Sculpting

Precision and Detail

Model making and sculpting allow for intricate and detailed designs to be brought to life, ensuring that every part of the model accurately reflects the intended design.

Custom Designs

Each model or sculpture can be custom-made to meet the specific requirements of the client, allowing for flexibility in design, materials, and finishes.

Visual Representation

Model making provides a tangible, visual representation of a product or idea, helping clients see and understand the final form before moving into mass production or further development.

Versatile

With the ability to work with a wide range of materials and create complex shapes, model making and sculpting are versatile enough to meet the needs of various industries.

For more information, call us at (973) 684-1501 or visit our

contact page.

Our Model Making & Sculpting Process

1. Design Concept

We collaborate with our clients to refine the design concept, ensuring that the model or sculpture meets all visual and functional specifications.

2. Material Selection

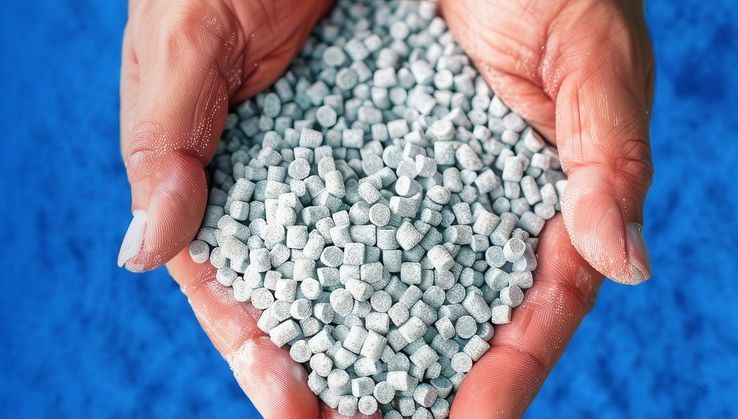

Based on the design and requirements of the project, we select the appropriate materials to ensure the finished model achieves the desired look, durability, and accuracy.

3. Sculpting & Model Creation

Using advanced tools and techniques, our skilled craftsmen sculpt and shape the materials to create a precise model or prototype.

4. Finishing & Detailing

After the initial model is completed, we add any necessary finishing touches, such as painting, texturing, or surface treatments.

5. Quality Inspection

Each model undergoes a thorough quality inspection to ensure it meets the client’s design specifications and is free from defects before moving on to the next stage.

6. Packaging & Shipping

The finished models are carefully packaged and shipped to our clients, ensuring they arrive in perfect condition and ready for use or presentation.

Experience the Excellence of American-Made Model Making & Sculpting

At Bennett Plastics, our commitment to quality, craftsmanship, and client satisfaction sets us apart in the model making and sculpting industry. Partner with us today to bring your creative vision or product prototype to life with the reliability and precision that only a trusted, local manufacturer can offer.

Sustainability for Innovative Manufacturing

We are dedicated to sustainability by using eco-friendly materials such as bio-based and recycled plastics in our manufacturing process, ensuring that our products meet high-quality standards and contribute to a healthier planet.

The Bennett Plastics Advantage

Direct Communication

Experience seamless collaboration with Bennett Plastics. We maintain open, direct lines of communication throughout the entire manufacturing process.

On-Site Manufacturing

All production is handled in-house at our Paterson, NJ facility. This allows us to maintain strict quality control and deliver products that meet our high standards.

No Outsourcing

Your projects are managed entirely by our skilled team. We never outsource, so you can trust that every part we produce is crafted with precision, right in the USA.

Fast Delivery

Our efficient processes and local manufacturing enable us to deliver your products quickly, reducing lead times and keeping your projects on schedule.