What Is Multi Jet Printing (MJP)?

MJP 3D Printing in New Jersey

Multi Jet Printing (MJP) is an advanced 3D printing technology that works by jetting liquid photopolymer materials onto a build platform, layer by layer. The material is then cured with a UV light to form precise, solid parts. MJP is known for its ability to create fine details, smooth surface finishes, and highly accurate components, making it ideal for prototypes, intricate designs, and functional parts.

The Benefits of Multi Jet Printing (MJP)

High Detail & Precision

MJP technology produces parts with exceptionally fine resolution, capturing intricate details and ensuring accurate geometries even for complex designs.

Smooth Surface Finish

MJP parts are known for their smooth, professional-grade finishes, reducing the need for extensive post-processing.

Material Versatility

With MJP, a variety of materials can be used, from rigid plastics to flexible elastomers, to meet specific design and functional requirements.

Efficient Support Removal

MJP uses wax-based support materials that can be easily removed without damaging the part, allowing for the production of complex geometries.

For more information, call us at (973) 684-1501 or visit our

contact page.

Our Multi Jet Printing (MJP) Process

1. Design Consultation

Bennett Plastics collaborates with you to understand your project needs and ensure your design is optimized for MJP technology.

2. Material Selection

We help you select the best material for your project, ensuring that the final product has the desired mechanical properties and aesthetic quality.

3. 3D Printing Process

Our advanced MJP printer jets layers of photopolymer material and cures them with UV light, building your part layer by layer with incredible precision.

4. Support Removal

After printing, the wax-based supports are melted away, leaving behind a smooth, clean part ready for use.

5. Post-Processing

Additional post-processing steps, such as polishing or painting, can be performed if necessary, depending on the application requirements.

6. Quality Assurance

Each part undergoes a thorough inspection to ensure it meets all required specifications before it is packaged and prepared for shipping.

Experience the Precision of MJP American-Made Manufacturing with Bennett Plastics

Partner with Bennett Plastics to leverage the benefits of Multi Jet Printing for your next project. Whether you need high-detail prototypes or intricate production parts, we offer the reliability and expertise you can trust.

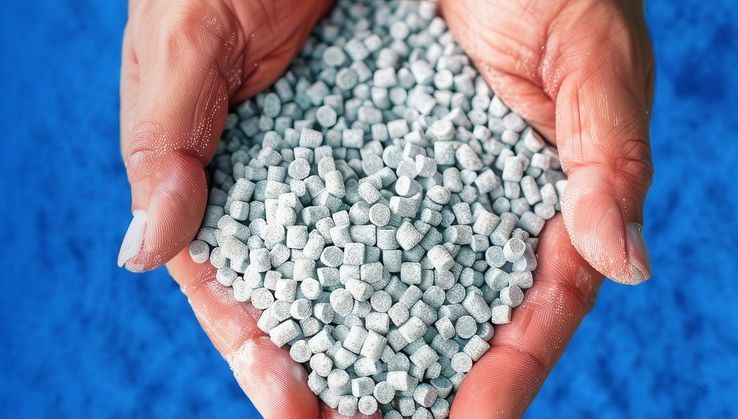

Sustainability for Innovative Manufacturing

We are dedicated to sustainability by using eco-friendly materials such as bio-based and recycled plastics in our manufacturing process, ensuring that our products meet high-quality standards and contribute to a healthier planet.

The Bennett Plastics Advantage

Direct Communication

Experience seamless collaboration with Bennett Plastics. We maintain open, direct lines of communication throughout the entire manufacturing process.

On-Site Manufacturing

All production is handled in-house at our Paterson, NJ facility. This allows us to maintain strict quality control and deliver products that meet our high standards.

No Outsourcing

Your projects are managed entirely by our skilled team. We never outsource, so you can trust that every part we produce is crafted with precision, right in the USA.

Fast Delivery

Our efficient processes and local manufacturing enable us to deliver your products quickly, reducing lead times and keeping your projects on schedule.