What is FDM?

FDM 3D Printing in NJ & NY

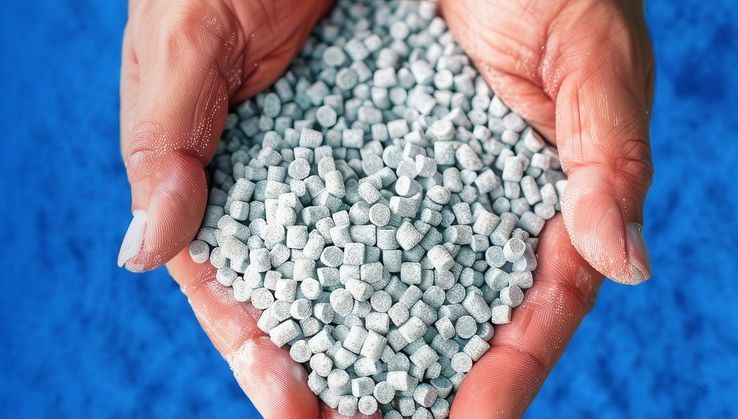

Fused Deposition Modeling (FDM) is a 3D printing technology that builds parts layer by layer by extruding thermoplastic material through a heated nozzle. This process is highly efficient and versatile, making it ideal for rapid prototyping and the production of durable end-use parts. FDM is widely used across industries such as automotive, aerospace, healthcare, and consumer goods due to its ability to create complex shapes and lightweight components.

The Benefits of Fused Deposition Modeling

Rapid Prototyping

FDM allows for the fast production of prototypes, enabling manufacturers to test designs, functionality, and fit before moving into full-scale production.

Cost-Effective

FDM is an economical 3D printing method, especially for low to medium production runs, with minimal waste and reduced labor costs.

Versatile

FDM supports a wide range of thermoplastic materials such as ABS, PLA, nylon, and polycarbonate, allowing for flexibility in mechanical properties and applications.

Customizable & Complex Designs

Highly customized designs can be achieved with precision, including parts with intricate geometries that are difficult to produce with traditional methods.

For more information, call us at (973) 684-1501 or visit our

contact page.

Our Fused Deposition Modeling (FDM) Process

1. Material Selection

We begin by working closely with you to refine the 3D design and select the most appropriate thermoplastic material.

2. 3D Printing Setup

Our engineers program the FDM 3D printer with your custom design, ensuring the correct settings for extrusion, layer thickness, and build orientation are optimized for your part.

3. FDM Printing

The FDM process starts with a heated nozzle extruding thermoplastic material onto the build platform layer by layer, creating a precise and durable 3D part based on your design.

4. Post-Processing

After printing, the part may undergo finishing processes like support removal, surface smoothing, or additional treatments.

5. Quality Inspection

Every part is subjected to a thorough quality inspection to ensure it meets all design and performance standards before being prepared for delivery.

6. Packaging & Shipping

The finished products are carefully packaged and shipped to ensure they arrive in perfect condition and within your required timeline.

Experience the Excellence of American-Made Fused Deposition Modeling

At Bennett Plastics, we take pride in offering top-tier FDM 3D printing services that deliver precision and durability. Whether you need rapid prototypes or complex, end-use parts, our expertise and advanced FDM technology provide reliable, cost-effective solutions for a wide range of industries.

Sustainability for Innovative Manufacturing

We are dedicated to sustainability by using eco-friendly materials such as bio-based and recycled plastics in our manufacturing process, ensuring that our products meet high-quality standards and contribute to a healthier planet.

The Bennett Plastics Advantage

Direct Communication

Experience seamless collaboration with Bennett Plastics. We maintain open, direct lines of communication throughout the entire manufacturing process.

On-Site Manufacturing

All production is handled in-house at our Paterson, NJ facility. This allows us to maintain strict quality control and deliver products that meet our high standards.

No Outsourcing

Your projects are managed entirely by our skilled team. We never outsource, so you can trust that every part we produce is crafted with precision, right in the USA.

Fast Delivery

Our efficient processes and local manufacturing enable us to deliver your products quickly, reducing lead times and keeping your projects on schedule.