What Is The FTMIP?

Cost -Effective Molding Solutions in NJ, NY, & CT

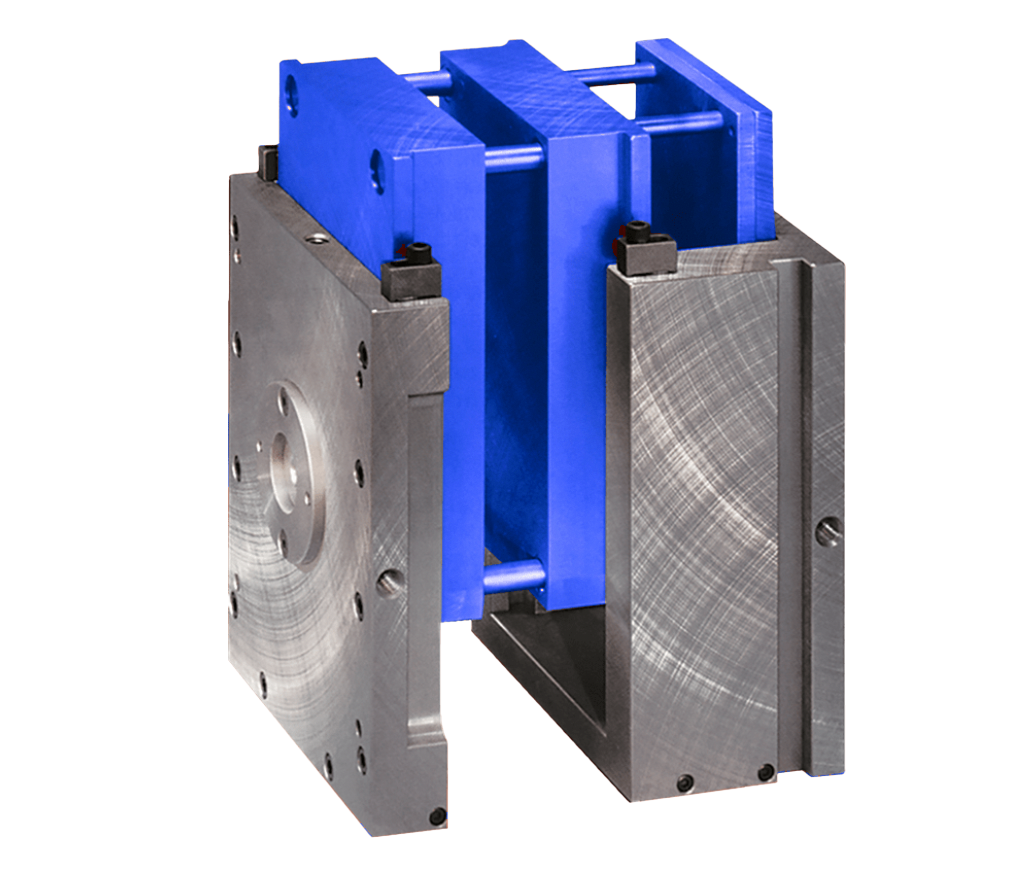

The Fast-Track Mold Insert Program (FTMIP) is a specialized system designed to provide a fast and cost-effective injection mold solution. Instead of creating a full custom mold base, which can be time-consuming and expensive, we build a custom mold insert that fits into one of our pre-existing mold bases. This significantly reduces the lead time and upfront investment needed to get your product molded and into production. With the FTMIP, you can have your custom-built mold insert and product samples ready in as fast as 5 weeks—giving you a quick, affordable way to get your product into the hands of consumers or investors..

The Benefits of FTMIP

Fast and Affordable

The FTMIP allows you to quickly prototype and test your product without the lengthy delays and high costs associated with traditional mold making.

Cost-Effective

Since the program uses pre-existing mold bases, you avoid the high costs associated with building a full custom mold from scratch.

Quick Turnaround

With product samples ready in as little as 5 weeks, you can get your product to market or into the hands of stakeholders much faster than with traditional tooling methods.

Flexibility

The Fast-Track Mold Insert Program is perfect for companies that require smaller production volumes, making it a flexible and scalable solution for a wide range of industries.

For more information, call us at (973) 684-1501 or visit our

contact page.

Our Injection Molding Process

1. Consultation & Review

We start by reviewing your product to ensure it fits within the program’s parameters. If your product is a good fit, we move forward with the custom mold insert design.

2. Mold Insert Design

Our engineers design a mold insert specifically for your product. The insert is built to fit into one of our pre-existing mold bases, allowing for a quicker and more cost-effective process.

3. Mold Insert Production

Once the design is approved, we create the mold insert and prepare it for production. This typically takes just a few weeks, thanks to our streamlined process.

4. Sample Production

After the mold insert is ready, we run the first batch of samples. You’ll receive these in as fast as 5 weeks, allowing you to test the product and make any necessary adjustments.

5. Testing & Refinement

Based on your feedback, we can make any necessary adjustments to the mold insert or production process. This step ensures the final product meets your quality standards.

6. Production

If the samples meet your expectations, we can move into full production using the same mold insert, producing up to 100,000 units per year. If larger runs are needed, we help you scale up.

Experience American-Made Manufacturing Today

At Bennett Plastics, our commitment to quality, precision, and customer satisfaction sets us apart in the injection molding industry. Partner with us today to bring your next project to life with the reliability and efficiency that only a trusted, local manufacturer can offer.

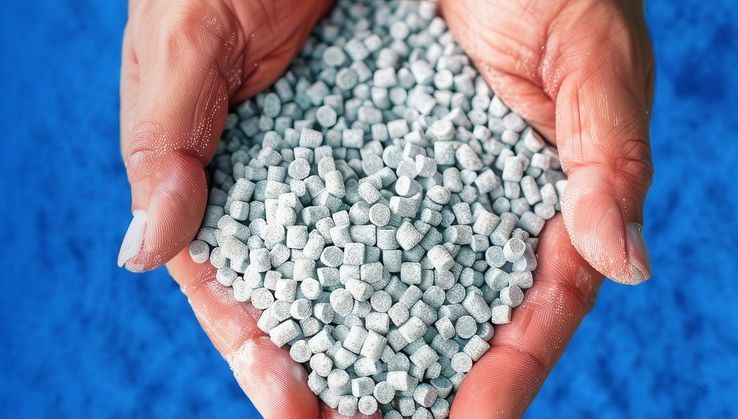

Sustainability for Innovative Manufacturing

We are dedicated to sustainability by using eco-friendly materials such as bio-based and recycled plastics in our manufacturing process, ensuring that our products meet high-quality standards and contribute to a healthier planet.

The Bennett Plastics Advantage

Direct Communication

Experience seamless collaboration with Bennett Plastics. We maintain open, direct lines of communication throughout the entire manufacturing process.

On-Site Manufacturing

All production is handled in-house at our Paterson, NJ facility. This allows us to maintain strict quality control and deliver products that meet our high standards.

No Outsourcing

Your projects are managed entirely by our skilled team. We never outsource, so you can trust that every part we produce is crafted with precision, right in the USA.

Fast Delivery

Our efficient processes and local manufacturing enable us to deliver your products quickly, reducing lead times and keeping your projects on schedule.