Plastic Injection Molding for The Electrical Industry

Safe Manufacturing Materials for Electrical Products

Bennett Plastics

specializes in plastic injection molding for electric and electronic components. We use the latest injection tools to provide our customers peace of mind when it comes to creating their products as efficiently and effectively as possible. Being in the plastic injection molding business since 1982, we have the expertise and the reputation to get your products fulfilled. We can take on any quantity of products needing to be produced and get them packaged and delivered out of our 36,000 square foot facility.

What Electrical Components Do We Currently Provide Injection Molding Services?

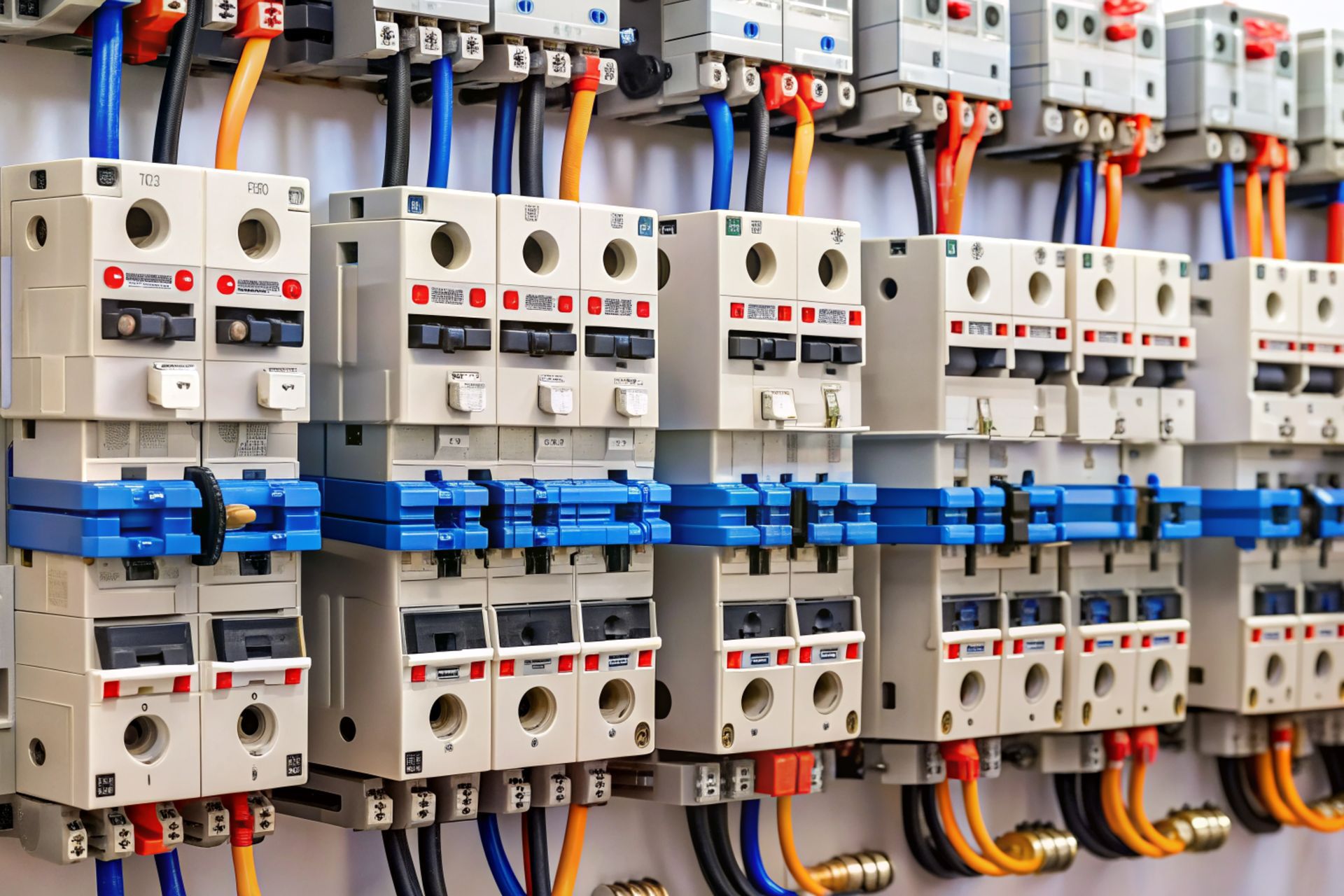

We provide plastic injection molding services for an array of electric & electronic components. Some of the electrical products that we currently produce are electrical housings (plastic housing that encases electrical components) timers, electrical machinery, and various electrical components & controls.

Numerous kinds of test equipment, lighting, sensors are important in electrical field. Manufacturing these parts correctly is integral in providing our customers with accurate arts that are high-performing. Electrical devices are needed for long term uses quality is key. And that is what we provide. Plastic is actually an ideal material for use in electronics because it can be either conductive or non-conductive plastic resin. When combined with watertight seals can be UV resistant with the ability to be used in flexible or rigid applications.

Common Applications of Polypropylene

Polypropylene's adaptability allows it to be used in numerous applications, providing durable, cost-effective solutions across various industries. Its balance of strength, flexibility, and resistance makes it a go-to material for many manufacturers.

Why Choose Bennett Plastics?

Choose Bennett Plastics for your electrical component needs, and gain the assurance of high-quality, American-made products built to meet rigorous industry standards. Our advanced plastic injection molding technology allows us to create precise and durable parts that ensure reliable performance and safety in electrical applications. At Bennett Plastics, we’re committed to delivering exceptional service and products you can trust for critical electrical applications.

Experience Excellence in Plastic Injection Molding for the Electrical Industry

When it comes to high-performance plastic components for the electrical industry, Bennett Plastics delivers unmatched quality, precision, and reliability. With our commitment to American-made products and decades of industry experience, we are your trusted partner for all of your electrical molding needs. From custom designs to strict quality control, we provide solutions that ensure the safety and durability of your essential products. Contact us today to learn how we can bring your project to life with excellence.

Get a Quote

Contact us today for a free estimate and see how Bennett Plastics can bring your product vision to life.

Materials

For more information, call us at (973) 684-1501

or visit our

contact page.

The Bennett Plastics Advantage

Direct Communication

Experience seamless collaboration with Bennett Plastics. We maintain open, direct lines of communication throughout the entire manufacturing process.

On-Site Manufacturing

All production is handled in-house at our Paterson, NJ facility. This allows us to maintain strict quality control and deliver products that meet our high standards.

No Outsourcing

Your projects are managed entirely by our skilled team. We never outsource, so you can trust that every part we produce is crafted with precision, right in the USA.

Fast Delivery

Our efficient processes and local manufacturing enable us to deliver your products quickly, reducing lead times and keeping your projects on schedule.