What Is Material Selection?

Plastic Injection Molding in NY, NJ, & CT

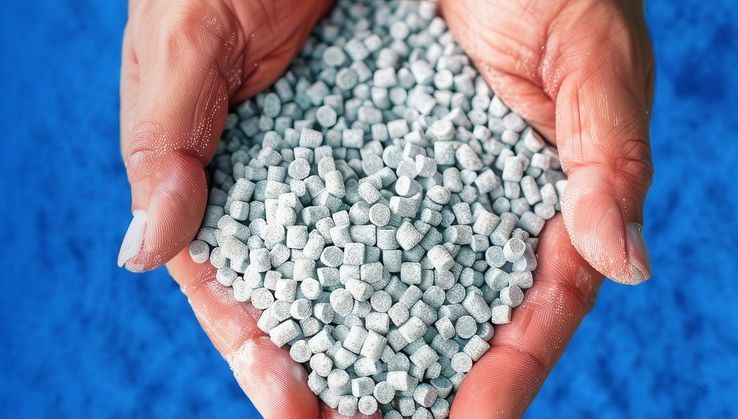

Material selection involves identifying the most suitable material for a product based on its design, functionality, and end-use requirements. This process is critical in plastic injection molding, where the material impacts everything from durability and flexibility to aesthetics and environmental impact. At Bennett Plastics, we work with a wide variety of plastics, ensuring that your product is manufactured to your exact specifications.

The Benefits of Material Selection

Enhanced Product Performance

By carefully selecting the right material, we ensure that your product performs as intended under the specific conditions of its use.

Cost Efficiency

The right material can reduce production costs by minimizing waste, improving manufacturability, and increasing the lifespan of the product.

Sustainability

We offer eco-friendly material options, such as bio-based, biodegradable, and recycled plastics, helping you meet sustainability goals and reduce your environmental footprint.

Industry Standards Compliance

We ensure that the materials we select meet all necessary regulatory requirements for your industry.

For more information, call us at (973) 684-1501 or visit our

contact page.

Our Material Selection Process

1. Product Requirements

We begin by assessing your product’s specific needs, including performance, durability, and environmental considerations.

2. Material Research

Our experts will present you with a range of material options, detailing their advantages and how they fit with your product.

3. Prototyping & Testing

Before finalizing the material, we produce functional prototypes using the recommended materials for thorough testing and evaluation.

4. Regulatory Compliance

We ensure that all materials meet necessary industry certifications, such as FDA compliance or UL certifications.

5. Final Material Selection

After prototyping and testing, we help you choose the optimal material for mass production.

6. Manufacturing Support

Once the design is finalized, we provide full support during the manufacturing phase, working closely with production teams to ensure a smooth transition.

Experience the Difference with American-made Products Bennett Plastics

At Bennett Plastics, we are dedicated to delivering high-quality material selection services that help you achieve optimal results for your injection molding projects. Whether you're developing a new product or refining an existing one, we’re here to ensure that your material choice enhances product performance, reduces costs, and supports your sustainability efforts.

Sustainability for Innovative Manufacturing

We are dedicated to sustainability by using eco-friendly materials such as bio-based and recycled plastics in our manufacturing process, ensuring that our products meet high-quality standards and contribute to a healthier planet.

The Bennett Plastics Advantage

Direct Communication

Experience seamless collaboration with Bennett Plastics. We maintain open, direct lines of communication throughout the entire manufacturing process.

On-Site Manufacturing

All production is handled in-house at our Paterson, NJ facility. This allows us to maintain strict quality control and deliver products that meet our high standards.

No Outsourcing

Your projects are managed entirely by our skilled team. We never outsource, so you can trust that every part we produce is crafted with precision, right in the USA.

Fast Delivery

Our efficient processes and local manufacturing enable us to deliver your products quickly, reducing lead times and keeping your projects on schedule.